With Spring term courses quickly transitioning to remote delivery, ╦┐╣Ž╩ėŲĄ, ŌĆ£╦┐╣Ž╩ėŲĄ Tech,ŌĆØ assistant professor Rich Carson had to find ways to still provide the hands-on focus that his Radiologic Science bachelorŌĆÖs degree program is known for. How does a program that requires hands-on interaction with patients transition to virtual delivery? Through collaborating with one of ╦┐╣Ž╩ėŲĄ TechŌĆÖs information technology experts, Scotty Hayes, to create a virtual environment. With this transformation, sophomores in CarsonŌĆÖs radiographic positioning class were able to navigate between three different camera options in the lab on campus to create a ŌĆ£hands-onŌĆØ environment.

With Spring term courses quickly transitioning to remote delivery, ╦┐╣Ž╩ėŲĄ, ŌĆ£╦┐╣Ž╩ėŲĄ Tech,ŌĆØ assistant professor Rich Carson had to find ways to still provide the hands-on focus that his Radiologic Science bachelorŌĆÖs degree program is known for. How does a program that requires hands-on interaction with patients transition to virtual delivery? Through collaborating with one of ╦┐╣Ž╩ėŲĄ TechŌĆÖs information technology experts, Scotty Hayes, to create a virtual environment. With this transformation, sophomores in CarsonŌĆÖs radiographic positioning class were able to navigate between three different camera options in the lab on campus to create a ŌĆ£hands-onŌĆØ environment.

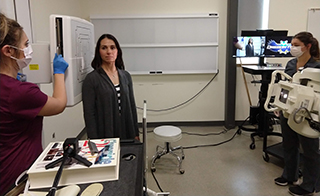

To evaluate the success of his new ŌĆ£classroom,ŌĆØ Carson used the setup to hold his end-of-term exams. Equipped with full protective gear, only three peopleŌĆöusually the same teaching assistantsŌĆöare in the room when each separate exam is conducted. This greatly limits any potential exposure a class of 50 students in the course would previously require, where students typically spend 50 to 100 hours each term in preparation for the competency exam.

The scenario:

- From his office in the Martha Anne Dow Center for Health Professions, Carson provides a health scenario to the student taking an exam through a Zoom call.

- A ŌĆ£patientŌĆØ shows up for their appointment at ╦┐╣Ž╩ėŲĄ TechŌĆÖs Radiologic Science lab to get X-rays from the virtual technologist.

- The student technologist completes an assessment with the patient over Zoom on basic health history and current complaints.

- During this time, two teaching assistants (TAs) standby in the room, awaiting instructions. These TAs are the hands of the student technologist.

- The student technologist instructs the TAs on positioning of the X-ray table and X-ray machine. The TAs quickly follow the exact instructions of the student technologist and are not allowed to make their own adjustments.

- The student technologist then asks the patient to lie on the X-ray table and provides verbal details to the patient on how to align their body.

- The student technologist conveys last minute adjustments to the TAs and the X-rays are taken.

- Carson then uses this to grade the exam.

While Carson increased the test grade required to pass the test from 75 percent to 85 percent, his students still passed with flying colors and many students completed the test within eight minutes of the allotted 12-minute maximum. He explains the situation with the following analogy: ŌĆ£Strap a GoPro┬« to the front of a car. Get in the back seat with a laptop watching the GoPro footage. Have someone drive without crashing into anything by following verbal instructions from the person in the back seat.ŌĆØ

The use of the cameras was also not a one-time thing. In her Mammography labs, department chair Debbie McCollam used the same setup to teach her junior students. Students instructed professor McCollam on how to position their Mammography phantom, ŌĆ£Bertha,ŌĆØ and instructed her as the technologist on hand position, where she needed to stand, how she needed to instruct the patient, machine operations, technique selection on the control panel, and computer set up.

Students in McCollamŌĆÖs course performed a second practical via this system, which focused on Quality Control procedures. The same process was implemented, instructing her as the technologist on how to set up the procedure on the computer, the Mammography unit, and the control panel for the technique. ŌĆ£Mammography is a difficult topic to teach without hands-on experience as proper positioning is completely reliant on the patientŌĆÖs body position, relaxation of the patientŌĆÖs pectoral muscle, and technologist hand placement,ŌĆØ shared McCollam. ŌĆ£I truly had no idea how this would turn out, but figured it was worth a try. I was thoroughly impressed how the students stepped up to the challenge and completed the task magnificently!ŌĆØ

A technician in ╦┐╣Ž╩ėŲĄ TechŌĆÖs information technology department, Hayes explains that the project was a collaborative effort, which included help from the universityŌĆÖs Manufacturing & Mechanical Engineering and Technology (MMET) department to create the custom solution Carson was looking for. ŌĆ£When Richard approached me for this project there were a lot of parameters that the design had to accommodate,ŌĆØ Hayes said. ŌĆ£Top items of this list are simplicity, portability and image quality. Nobody offered exactly what we needed, so I looked in-house to design and make it.ŌĆØ Hayes reached out to Phil Dussel in MMET to help with design and mechanical needs for integrating the technology into a physical product. ŌĆ£Phil was able to build upon the features provided by the manufacturer and create custom mechanical components to allow me to build a truly integrated solution.ŌĆØ

As sophomores, students in the course who passed CarsonŌĆÖs examŌĆöwhich in this case was all studentsŌĆöwill still rejoin the program in the Fall and take the exam in-person to comply with American Registry of Radiologic Technologists standards and requirements, but they continue to move forward in their courses and are not a term behind due to the unforeseen COVID-19 circumstances.

Watching CarsonŌĆÖs exam, one thing becomes readily apparent: there is limited to no physical contact between the patient and TAs. While all instructions are provided verbally by the student technologist, the future radiologic technologists are quickly learning how important verbal instructions are and how to clearly communicate with patients. McCollam also discovered this during her courses and plans to integrate additional training on verbal instructions into her future classes. She shared, ŌĆ£I found that when the students took the time to organize their thoughts and find the right technical terms to describe the steps to the procedure, they had a much greater understanding of how to correct problems when they occurred. In the future, I will incorporate more verbal description training along with physical positioning.ŌĆØ

Carson plans to keep the virtual system in place for future use, integrating it into his courses and he has also had discussions about the possibilities the system presents. ŌĆ£With this system or one like it, it could be integrated into a portable X-ray system that could have applications for developing nations,ŌĆØ said Carson. ŌĆ£IŌĆÖm looking forward to bringing this system into courses in the future. I cannot thank ITS and Scotty enough for their help with this system and for ensuring that students in my program did not fall behind in their coursework.ŌĆØ

McCollam agrees that the camera system proved to be a very effective method of teaching. ŌĆ£Our motto has always been, ŌĆśsee one, do one, teach one,ŌĆÖŌĆØ she shared. ŌĆ£The cameras allowed for that during a very critical time. Students were able to watch me do a procedure in a video recording, practice in their homes with whatever they had to work with, and solidify their knowledge by teaching me, as the technologist, in how to properly perform a Mammogram and a Quality Control procedure. I was thoroughly impressed with the results.ŌĆØ

###

╦┐╣Ž╩ėŲĄ ╦┐╣Ž╩ėŲĄ

Founded in Klamath Falls in 1947, ╦┐╣Ž╩ėŲĄ, ŌĆ£╦┐╣Ž╩ėŲĄ Tech,ŌĆØ is the premier polytechnic university in ╦┐╣Ž╩ėŲĄ. ╦┐╣Ž╩ėŲĄ Tech provides bachelorŌĆÖs and masterŌĆÖs degree programs in engineering, health technologies, business, technology, communication and applied sciences that prepare students to be effective participants in their professional, public and international communities through applied, relevant learning and professional practice. ╦┐╣Ž╩ėŲĄ Tech has a central, residential university in Klamath Falls; an urban, industry-focused campus in Portland-Metro (Wilsonville); an Online campus; and offers degrees at Boeing Seattle and at other sites. Visit www.oit.edu to learn more about ╦┐╣Ž╩ėŲĄ.